Usecase

Description

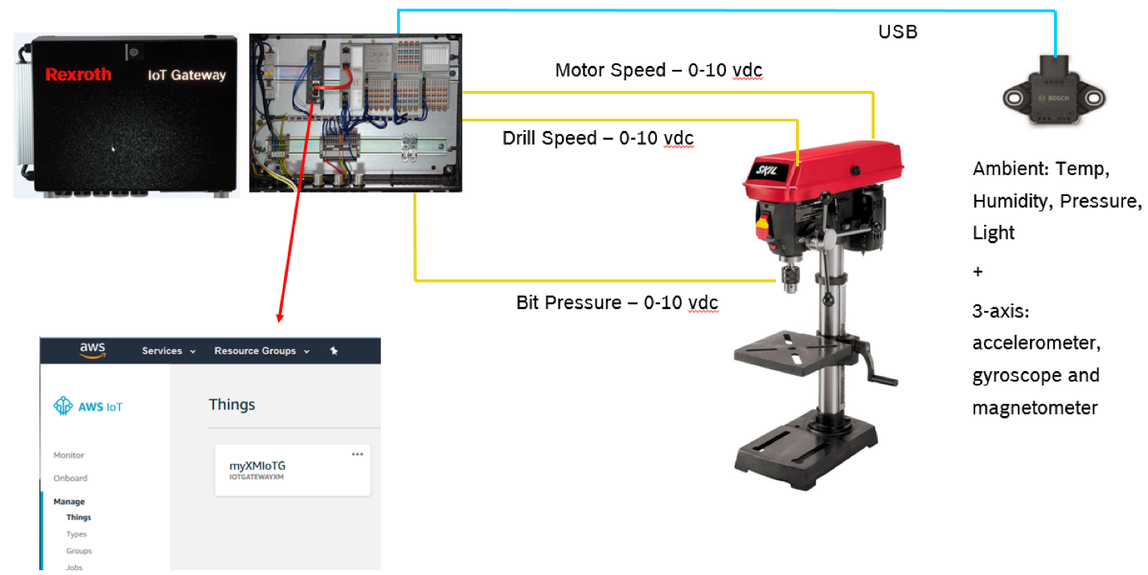

We have an industrial drilling machine use case that has sensors attached to it. There are several of them, but the relevant ones for this exercise are measuring the pressure on the drill and the RPM of the motor and the spindle.

The purpose of the workshop is to predict 'wrong' drilling which means where the motor rotates to fast/slow or that the drill duration took too long and so on.

We will connect to the PLC which controls the drill - get the data, analyze it and create an ML model which detects anomalies in the drilling process. Afterwards we will deploy the model to the edge and do the prediction at the edge. This enables users of the drill to avoid malfunctions and reduce the wear&tear on the equipment. More generally, the use case covers the main steps for any industrial predictive maintenance use case and how to implement such a use case end-to-end using AWS.

Physical Architecture

This picture shows the IoT gateway on the top left corner. This gateway will run Greengrass and allow us to read sensor values produced by the drill, or more specifically, the sensors attached to the drill. The first part of this workshop will focus on connecting the gateway to AWS IoT Core and getting the sensor data into the cloud while the second part aims to develop a machine learning model based on the recorded sensor data. Finally, the ML model will be used to detect drilling anomalies automatically, i.e., deploy a machine learning model on the gateway.